MECADEMIC - experience cutting-edge robotics in action

At the trade fair, NEXT presents one of the world’s most compact and precise industrial robots. Perfect for applications with the highest demands and minimal space. See firsthand how efficiency and simplicity are being redefined.

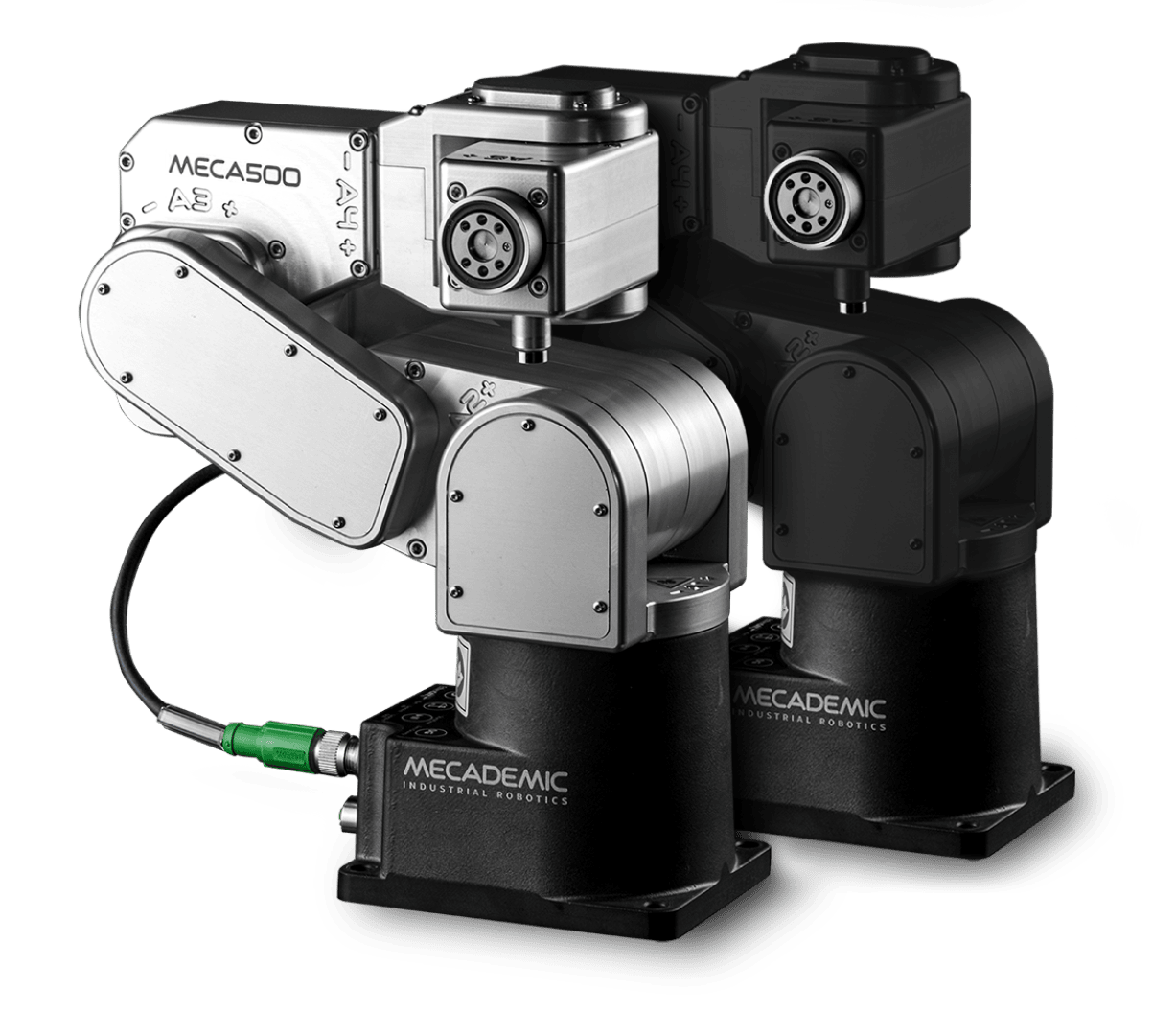

The Meca500 in use for demanding alignment and handling processes

The increasing miniaturization of optical components requires maximum precision in production. Even the smallest misalignment can impair the function and efficiency of optical systems - particularly in areas such as telecommunications, medical technology, consumer electronics and laser technology.

The Meca500 offers the necessary performance for these applications:

With a repeat accuracy of 5 µm, high rigidity and a low-vibration design, the robot is ideal for precise alignment and handling processes in the sub-millimeter range.

Thanks to its compact design with integrated controller, the Meca500 can be easily integrated into confined laboratory and production environments. The OBSI version is particularly relevant for light-sensitive applications: The deep black surface absorbs up to 96.5% of visible light and thus reduces reflections in the process environment to a minimum.

In an automated alignment cell we show the Meca500 in combination with:

- Vision system for component recognition

- Force control for sensitive adjustment

- Active feedback for repeatable adjustment

Typical application examples include

- Alignment of optical fibers

- Alignment of optical components

- Handling of micro-optical assemblies

The Meca500 combines precision, stability and compactness - ideal for applications in photonics where every micrometer counts.