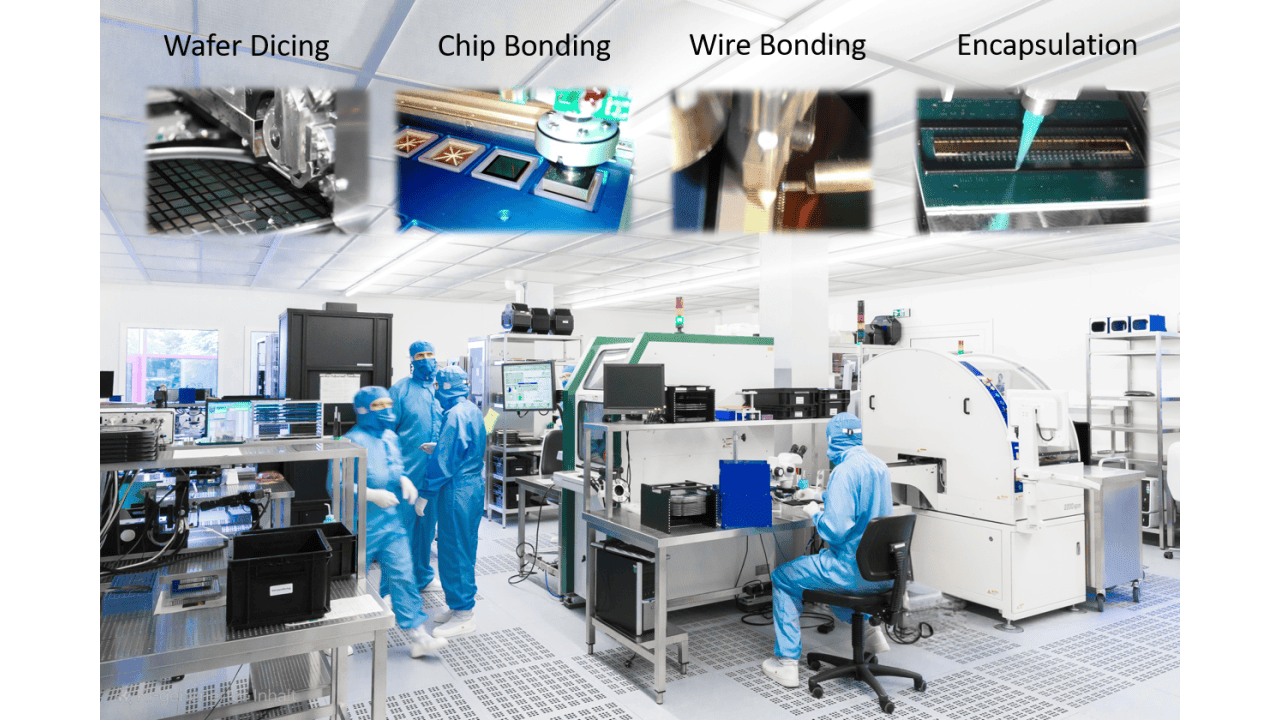

Fast Prototyping Service @ AIM Micro Systems GmbH

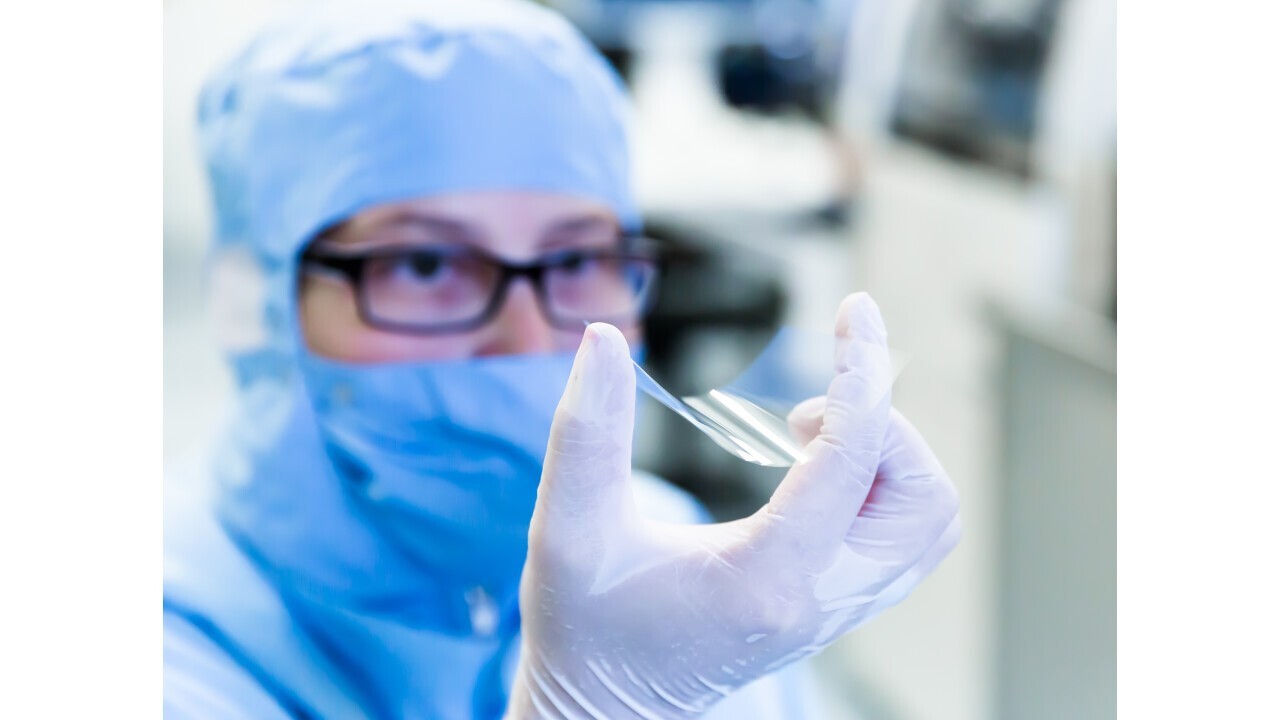

AIM Micro Systems GmbH offers Fast Prototyping Service. Depending on the product, we can provide this service between 12 days and down to 24 hours starting from wafer dicing to chip and wire bonding to encapsulation. All process steps take place in the ISO5 (class 100) clean room

AIM Micro Systems GmbH

Triptis,

Germany

AIM Micro Systems GmbH offers a comprehensive range of advanced technologies, including:

- Wafer Dicing: Precise cutting of wafers into individual chips.

- Chip & Wire Bonding: Connecting the die to the substrate or packaging through wire bonding techniques.

- Encapsulation: Protecting sensitive components from environmental factors by enclosing them in a protective layer.

- Final Test: Thorough testing of the assembled products to ensure they meet quality standards.

- Tiling of Image Sensors: Arranging multiple image sensors to create larger, seamless imaging surfaces.

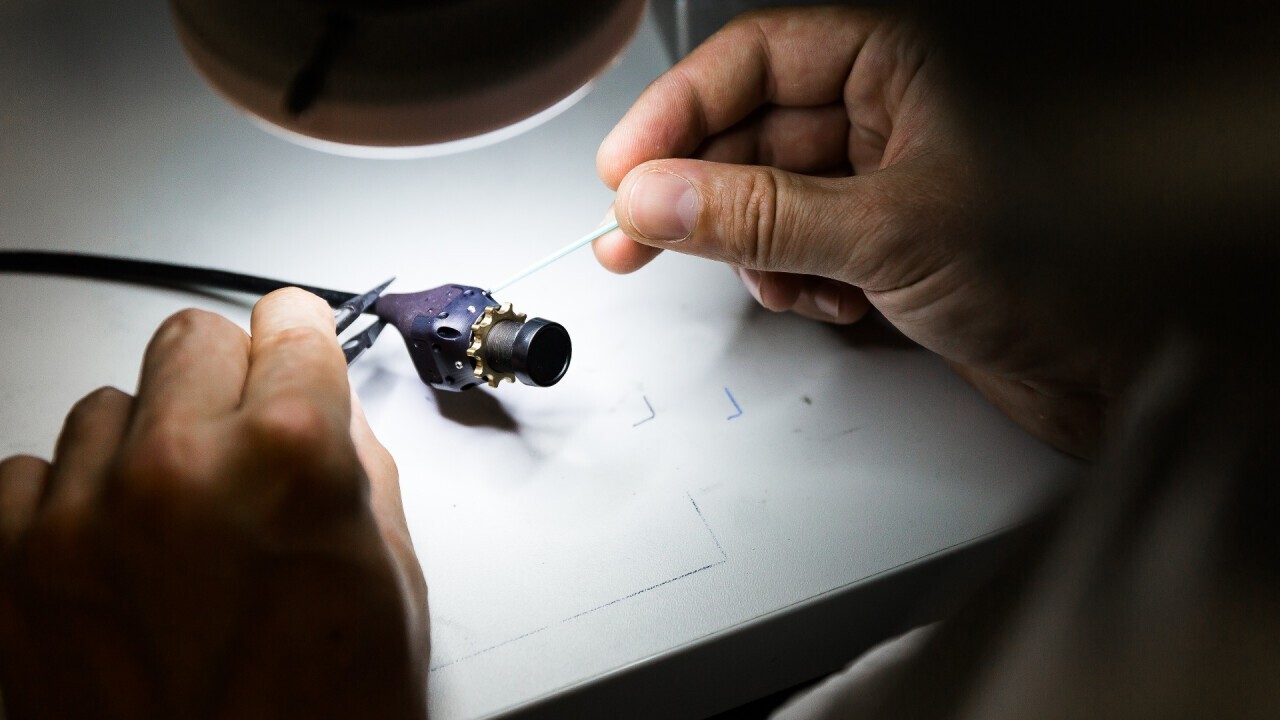

- FOP (Fiber Optical Block) Attachment: Integrating fiber optical blocks with image sensors for enhanced optical performance.

- Fast Prototype Service: Offering rapid prototyping with turnaround times as quick as 24 hours.

- Specialization in Medical and Space Applications: Expertise in meeting the stringent requirements of medical devices and space technology.

These capabilities make AIM Micro Systems GmbH a versatile partner for industries demanding high precision and specialized assembly services.